Truss Design - Truss Types and Benefits

In its most basic form, a truss is a structure that is taking advantage of the inherent stability and the weight distribution of triangle. The web of such triangles can be joined, and resulting effect causes stress to be evenly distributed across the entire structure that can be dramatically more lightweight than the walls created from strong materials.

By utilizing this approach, enormous weight and stress can be safely held by the load-bearing beams, walls or ground, even when outside forces such as the wind (noticeably present truss structures placed on tall buildings) or vibrations (swaying of bridges due to traffic or the wind). Those uneven forces are safely distributed across entire truss structure. Ever since first truss structures became first used in Ancient Egypt and more commonly found in the architectural project all across Roman Empire, they became an integral part of modern architecture on which many modern structures are built, including homes for billions of people all around the world.

Truss is a framework structure that distributes the load by taking advantage of the inherent stability of a triangle.

Truss Benefits

Trusses are an integral part of modern architecture and building. Since they can carry so much weight by themselves, their presence enables builders to achieve maximal economy of materials, easily cover large distances with simple truss meshes, evenly take the load from heavy structures, easily access entire structure, save on expensive materials, and build structures that are accessible for maintenance after initial construction.

Wooden trusses are most common and can be found in the housing industry as one of the most common architectural designs for carrying roof or ceiling structures. Trusses made from wood are considered incredibly useful because they can be easily constructed quickly on site, with very little cheap and accessible material needed to create the structure that can carry large weight load. Wood trusses can be used to span distance of up to 35 meters, which is more than enough for the creation of very durable and long-lasting bridges.

Truss enables the creation of light structures that can span large distances and endure very heavy loads.

Basic types of truss:

Simple – A truss created from the single triangle, often used for building lighter roofs, supporting ceiling structures, or providing strength to the metal frame of bicycles (the core of every modern bicycle design is a single triangle between seating position, pedals and handles, and additional triangle that connects core triangle to the rear wheel) and many other lightweight structures (like airplanes).

Planar – By connecting more truss triangles, we get planar structures that share the load that is placed on them. Most commonly, the planar design consists of the single repeating pattern and are most commonly used fro building of roofs and bridges.

Space Frame – Truss designs can also be made in 3 dimensions, with tetrahedron being the most simple and commonly used of space truss. It consists of six distinct elements that that meat at four joints. The mesh of space frame elements is most commonly used in the construction of “floors” built on top of just a few load bearing points that need to carry very large weight on top of them.

Truss Types

All truss structures can be placed into two basic categories of the common truss (created from repeated triangles) and flat truss (in which custom designed arrangement of triangles is placed between parallel top and bottom chords). However, over the last two thousand years, engineers and architects have devised dozens upon dozens of truss design approaches that are today used in various structures ranging from house floors and ceilings to the bridges, hangars, buildings, infrastructure objects and transportation vehicles from simple bikes to space rockets. Most popular truss types used today in modern construction are:

- Allan truss – Created as an evolution of Howe trusses (where diagonals slope toward the center of the bridge), first bridge of this design was created in August of 1894 in Australia by civil engineer Percy Allan who during his career designed over 580 bridges. Alan truss designs multiply the number of Howe trusses, enabling the creation of much longer bridges that are supported by one or more support points.

- Bailey bridge – Originally designed during WWII for easy assembly on site during military engagements using pre-fabricated parts. Today, timber and steel versions of these bridges are used for used for carrying pedestrians, road and rail vehicles.

- Baltimore truss – A variation of Pratt trusses that utilizes an additional bracing in the lower sections of the bridge truss network. It is used mostly for carrying rail transport.

- Bollman truss – Very rare truss type that survives today in the only bridge of its design left standing. Bollman Truss Railroad Bridge in Savage, Maryland features revolutionary all-metal design.

- Bowstring truss – Patented in 1841, bowstring is one of the most popular truss designs for smaller truss bridges.

- Brown truss – Very popular truss design that features diagonal cross compression members that are connected to the horizontal top and bottom stringers. They are mostly used for bridges made from wood, most notably covered bridges.

- Burr arch truss – Another truss design that is used a lot in the creation of covered bridges. In addition to the traditional planar triangle truss design, it also features an arch that gives entire structure additional strength and rigidity.

- Cantilevered truss – A truss network that is placed on the cantilevered bridges, whose main decks are heavily anchored from the central vertical spars. Most bridges of this design have trusses placed both above (where construction is placed under compression) and below (where the bridge is placed under tension) the main decks of the bridge.

- Fink truss - A unique looking truss design that is placed only under the decks of bridges (usually intended for carrying train or road vehicle transport). At the time of its creation in 1860, a Fink truss enabled the creation of the longest all-iron bridges in the world.

- Howe truss - A very popular truss type in which features triage diagonals that slope upward toward the center. Many smaller bridges and architectural solutions for homes feature this simple design.

- K-truss – Bridge type that features several types of triangles, who in the center of the structure from the normal and inverted character of “K”

- Kingpost truss – An evolution of the easiest to make “Simple” truss, which is enhanced with a single vertical support line.

- Queenpost truss – Similar as Kingpost truss, but with added horizontal extension that separates two diagonal outer supports.

- Waddell truss – Another very simple truss design. It uses a single tall triangle that is reinforced with two inward-facing triangles.

- Lattice truss – This truss type demands use of a large number of small and closely spaced diagonal elements that form a lattice. This design is usually used for the creation of lightweight structures (made from wood, iron or steel) such as smaller bridges or hangars.

- Lenticular truss – Design of this truss type consists from a big lens-shape truss that is elevated above the main deck of the bridge. This lens is separated into two parts, with both upper and lower arches having their network of trusses. If the deck of the bridge is placed in the middle of the lens, then that bridge is called lenticular pony truss.

- Long truss – Based on the Howe Truss, but made exclusively from wood. The longest surviving bridge of this type is Eldean Covered Bridge north of Troy, Ohio. Built in 1860, this bridge spans the distance of 68 using one central anchor point.

- Parker truss – This is a very popular truss design that instead of the smooth arch features rigged arch that directly connects the edges of the truss mesh. It closely resembles bowstring arch truss. It is also known as camelback truss design.

- Pegram truss – This is a hybrid of Pegram truss designs, with the most notable difference is that upper chords are all of the equal lengths, and lower ones are longer.

- Pennsylvania (Petit) truss – Truss type whose lower section of the mesh are additionally reinforced with additional triangles.

- Pratt truss – Very popular truss design where diagonal supports slope down toward center (while in Howe trusses are pointing in the opposite direction). This design enables the creation of structures that have spans of 76 meters between anchor points. Bridges with this design were very commonly made between a middle of 19th and early 20th century.

- Thatcher truss – A rare variation of Pratt and Howe truss design.

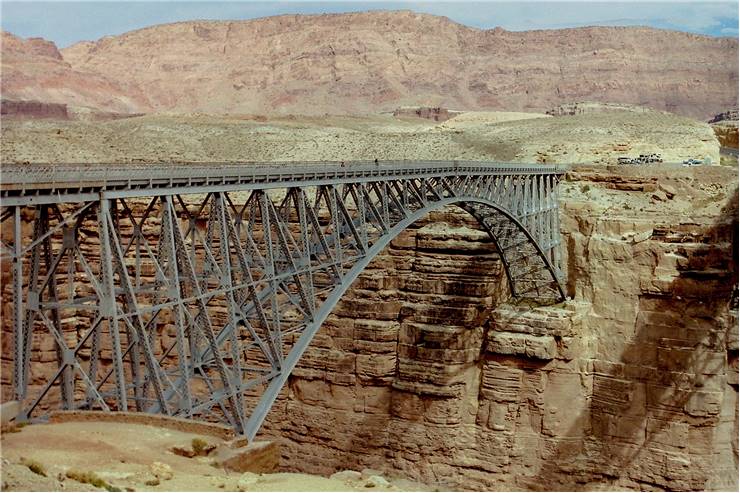

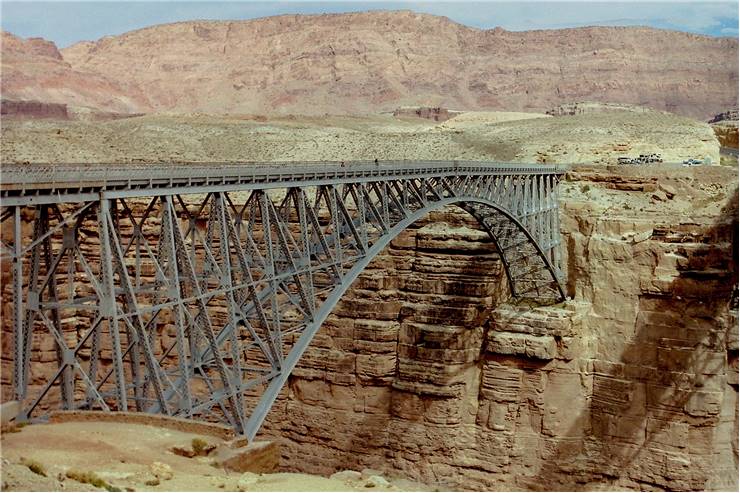

- Truss arch - An arch bridge whose inverse arch is built from the truss mesh below the main deck of the bridge. Vertical supports connect this arch to the decking. It can be used for the creation of medium-sized bridges that can even carry heavy railroad transport.

- Vierendeel truss – A truss design that does not uses regular triangular elements, but rigid rectangular openings and strong reinforcements from other elements and connectors. Today it can most commonly be found only in Belgium. Only one movable bridge of this design exists today.

- Warren truss – A very simple truss design that consists of two parallel chords and equally sized triangles placed in between. This effective design is popular not only in construction but also in production countless other machines and systems. For example, early two-winged airplanes used lightweight Warren truss mesh to reinforce the structure of the wings.

- Whipple truss – Another variation of the Pratt truss design, but made with vertical bars that are held together with an array of diagonal members (lightweight and put at a shallower angle that enables them to cross one or more vertical bars) designed to work together to alleviate tension from the rest of the structure.